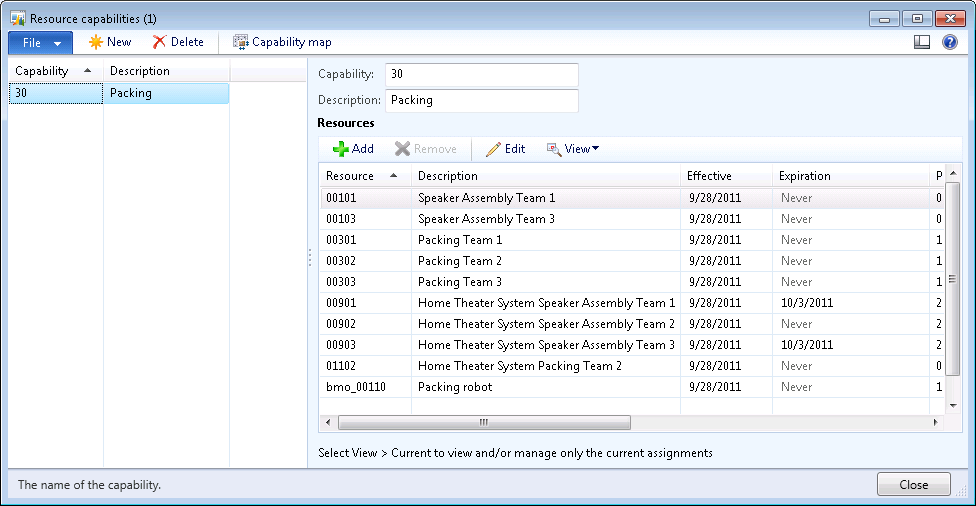

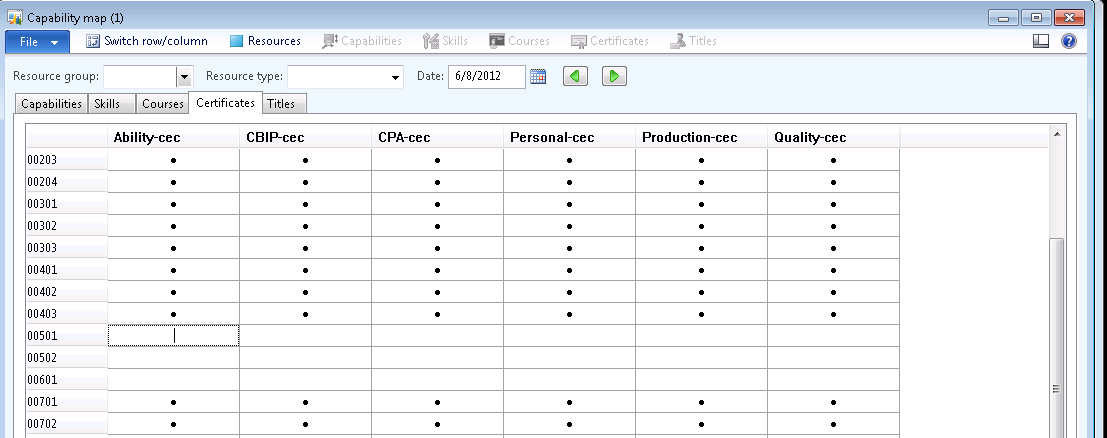

In my previous blog on the resource model in Dynamics AX 2012 (part 1) the extension of resource types and resource capabilities have been explained. Also, a short introduction on resource planning is given. In this blog I will elaborate on the resource planning in more detail.

Dynamics AX 2012 provides more features to optimize the production planning process in your organisation. One of these features includes the ‘property’ concept. This helps the planning process in case a manufacturing process should be tailormade for a specific customer.

The property feature in Dynamics AX 2012 gives the ability and important advantages including

- Sequential planning of work orders in order to minimize required time for setup between the job operations;

- Optimizing job sequencing to the same resource at the shop floor;

- Scheduling and rescheduling of work orders and jobs can be managed in an improved way.

To realize the property based production and job schedule the following configurations are prerequisite and can be managed easily in Dynamics AX2012:

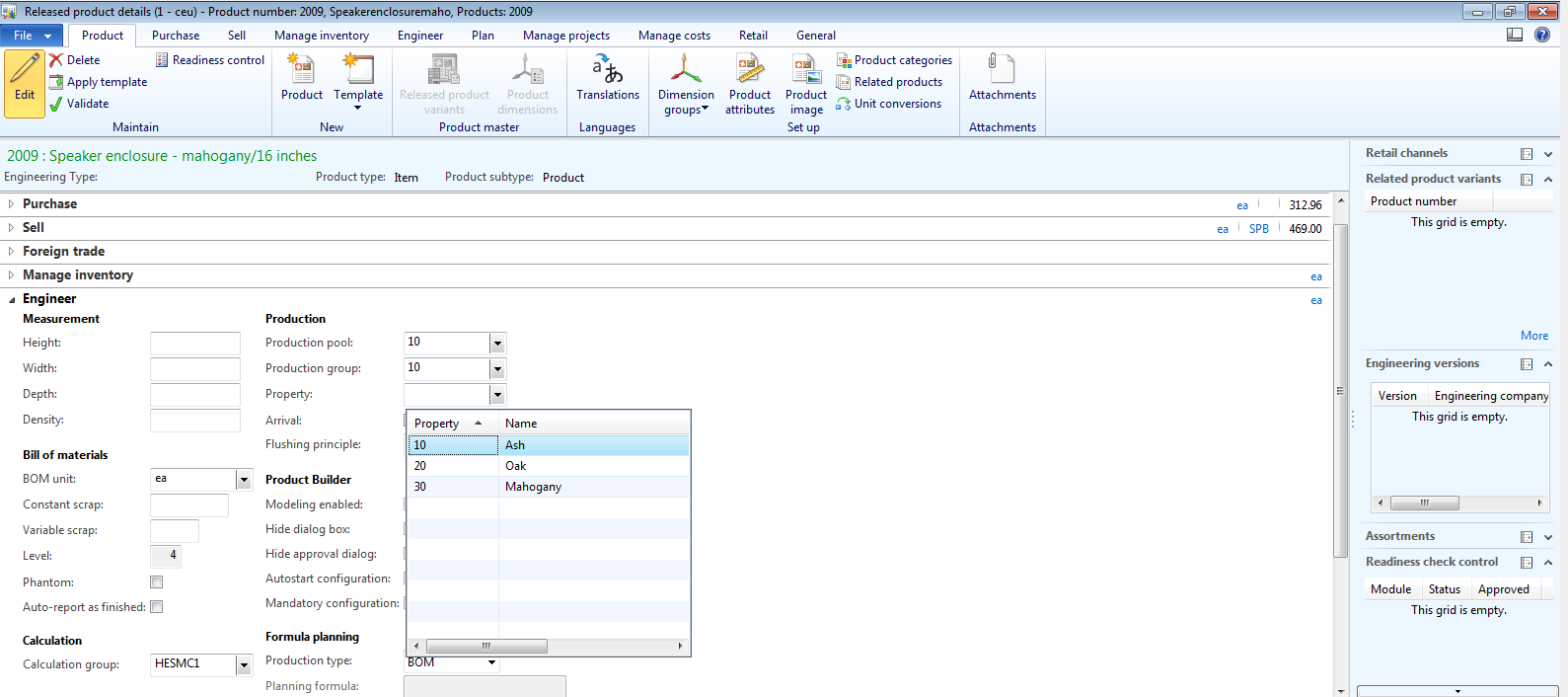

Assigning a property to a Product

A product property can be used to classify it as a tailor made product or to assign a specific product attribute. This feature can be used to activate production routes which are property based.

Path: Product Information Management > Released product details > Engineer fast tab

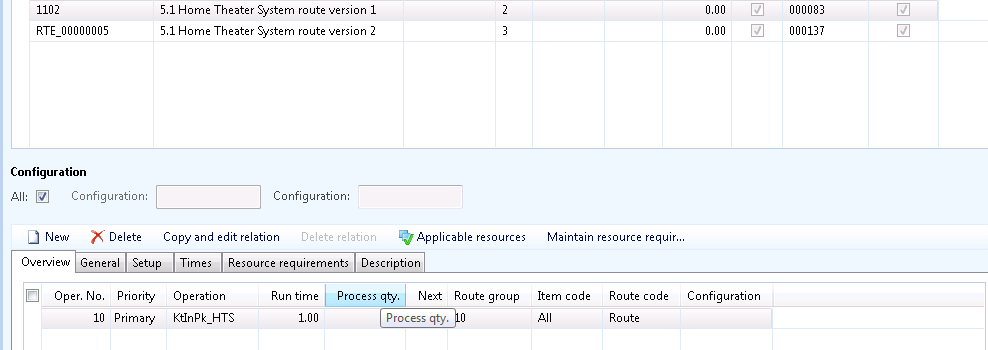

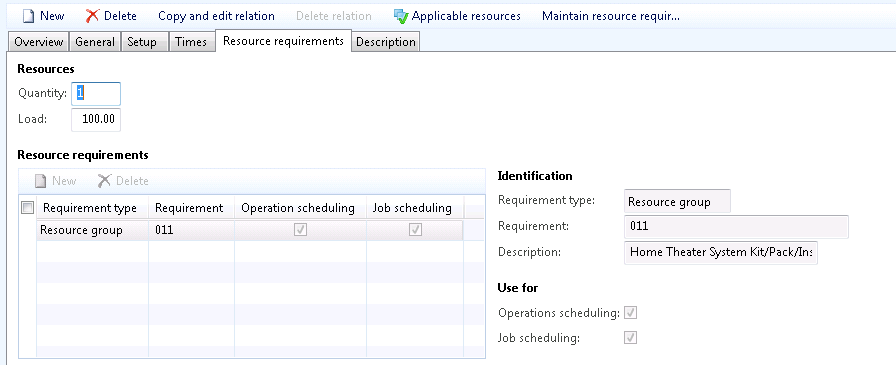

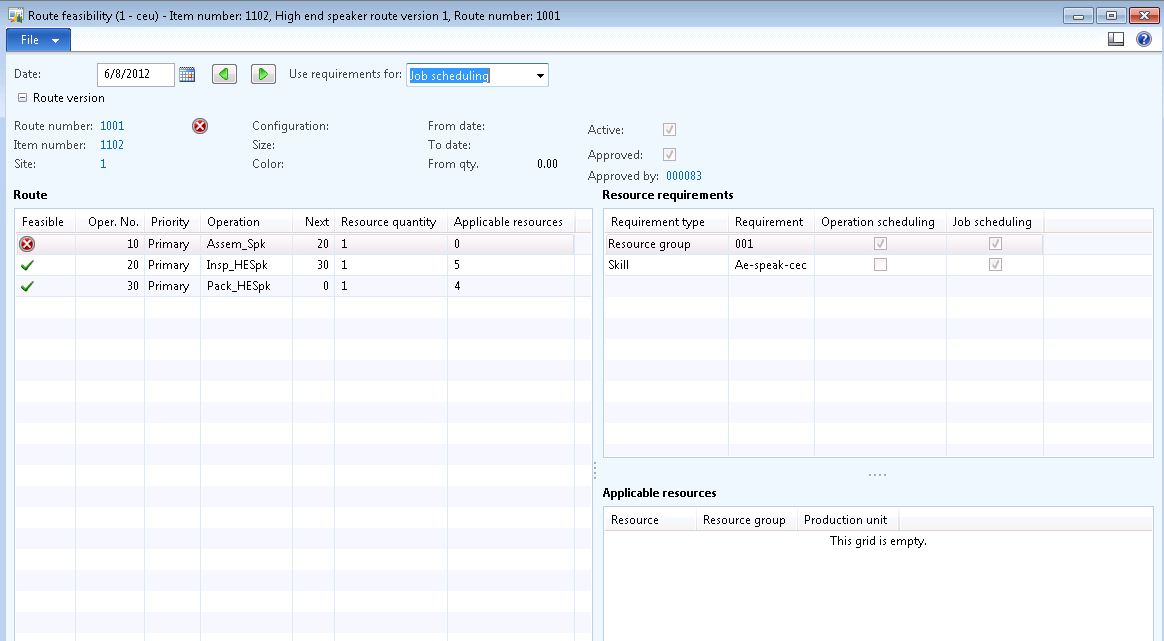

Assigning the property to the route operation and the production

Dynamics AX 2012 enables to differentiate job operations (part of the route) and products which are property specific. This simplifies maintaining job routes for customer specific use or to differentiate product specific manufacturing operations.

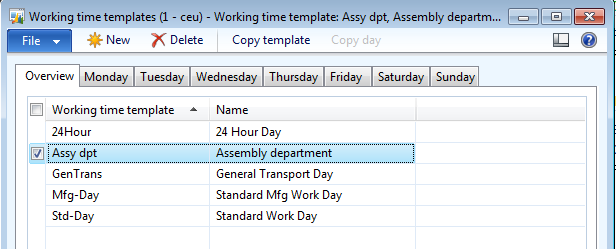

- Job scheduling based on predefined timeslots

In case a work order and jobs are restricted to be scheduled during a specific period of days or hours the same set of properties can be assigned to predefined working time templates. These working templates can easily be updated and assigned to the working template.

Path: Organization Administration – Common – Calendars – Working time templates – ‘overview’ tab

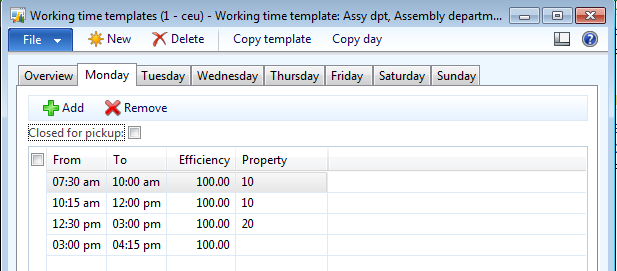

Dynamics AX 2012 enables that job scheduling can be based on time intervals based on product specific properties. During the job scheduling the correct property will be considered based on the time intervals. In the example below the property ‘10’ assigned operations and/ or product will be scheduled during the Monday morning.

Path: Organization Administration – Common – Calendars – Working time templates – ‘Monday’ tab

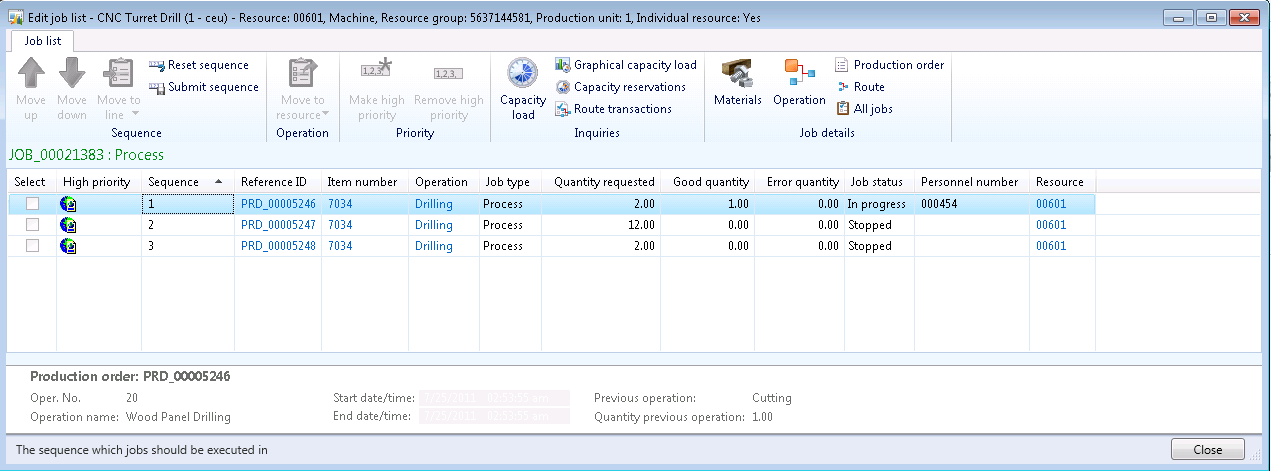

Impact of property scheduling on resource scheduling

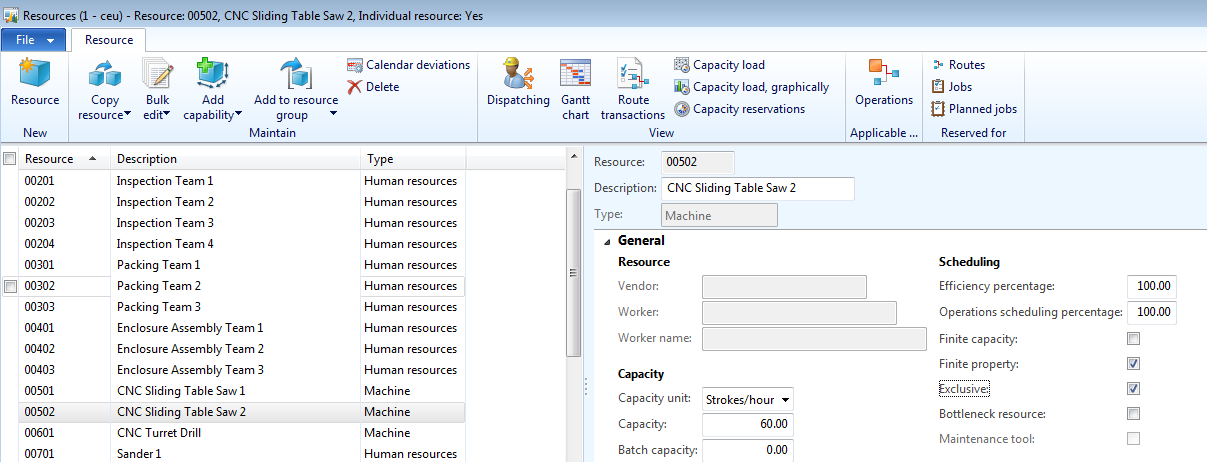

If jobs can only be performed by specific resources based on the property rules setup and resource needs to be allocated then this can be managed in the resource master data. Also the scheduling of job orders considers the capacity availability based on efficiency parameters of a certain resource which can be human resource, machine, tool, location or other types.

The MRP process will schedule planned work orders based on the finite and infinite planning rules which are applicable for materials, resources AND property based allocation. At the same time resources will be allocated for that specific job in order to ensure on-time delivery. If the resources can only be scheduled during specific timeslots in the week the working time templates (see 3.) helps optimizing this.

In the example illustration above the resource 00502 will be allocated for specific products based on the property principle.

Pad: Organization Administration – Resource – Resource